story by Eric Nelson and Mark Worth

photos by Neal Herbert, research assistance by Andrea Helm

The Free Press

Faye Schrum and untold dozens of current and former Boeing workers continue to live with medical problems - ranging from nausea and nose bleeds to impaired vision and brain damage - they blame on chemicals at the Auburn plant, the top-secret Developmental Center in south Seattle and other Boeing facilities. And, like four years ago, many of them continue to fall through the cracks of a system that, on paper, was designed to help workers who have been hurt on the job.

"The Boeing Company meant everything to me," said Heidi Guevara, a plastic bench mechanic who got sick at Auburn in 1987. "It was a big letdown. I figured they would take care of it."

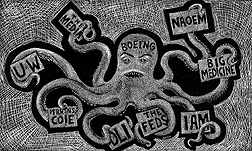

A Free Press investigation has revealed that the very system designed to help injured workers is being influenced by a closed loop of powerful institutions - most significantly Boeing, the University of Washington's School of Medicine and the Washington State Medical Association. Also in on the act are high-powered law firms, industry-friendly medical researchers, and doctors who straddle the line between physician and corporate apologist.

Working in concert, Boeing and "Big Medicine" are using their economic power and political clout to manage the high-stakes debate over Multiple Chemical Sensitivity (MCS), a complicated occupational illness with unpredictable effects. Key to their strategy is framing MCS primarily as a psychological condition, despite a growing body of medical and scientific evidence to the contrary.

Making matters worse, some MCS sufferers complain, the International Association of Machinists and Aerospace Workers has been largely unresponsive at a time when disabled workers need the union's help the most. (See related story: "Disunity Among the Machinists").

Fully aware of the huge financial stake that it has in debunking the existence of MCS, Boeing is making its imposing presence felt at the Washington Department of Labor and Industries (L&I), which oversees the

|

'I've watched how unsympathetic the power structure has been. It's scary.' Sue Ammeter, the governor's Committee on Disability Issues and Employment

|

Rather than endure the physical and emotional pain wreaked by MCS, several Boeing workers have taken their own lives (See related story: "Suicide Solution - One Woman's Way Out"). Others manage with the help of support groups that have formed throughout Puget Sound.

"I have a close friend who has MCS, and I've watched how unsympathetic the power structure has been," said Sue Ammeter, chair of Gov. Mike Lowry's Committee on Disability Issues and Employment. "It's scary."

Some of the sick Boeing workers have filed federal discrimination complaints, asking that authorities investigate the Labor and Industries department.

The connections that link Boeing with Labor and Industries have raised serious questions about the department's objectivity.

"They are well-coordinated on the other side," said Matt Sweeting, a Tacoma attorney who has represented many people with MCS. "The connections are very insidious."

Consider:

- L&I Associate Medical Director Henry "Hal" Stockbridge helped direct a controversial, Boeing-funded study that implies MCS sufferers are essentially deluding themselves into being sick. Interestingly, the study fell into the hands of a Boeing-hired attorney working on an MCS case before the results were published.

- Dr. Patricia Sparks, a high-profile toxicologist, is on the payrolls of both Boeing and L&I. In addition to Boeing, Sparks has consulted for other chemical-intensive industries that stand to benefit from theories that question the legitimacy of MCS. She has also advised the state Medical Association on its MCS position papers.

- And two of L&I's top medical experts - both of whom work intimately on MCS issues for the state - sit with a former high-ranking Boeing doctor on a panel affiliated with the state Medical Association, state records show. The panel also is linked to a prominent Seattle law firm that is battling chemically injured workers in court, and an organization that performs psychological tests on Hanford whistleblowers, records show.

"Pushing the position that these sick workers basically are psychologically impaired are people who seem to have a stake in that position," said Stephen Gockley of the governor's Committee on Disability Issues and Employment.

"I don't think there is any question that acknowledging the reality of MCS would have potential financial consequences," Gockley said, adding that businesses that use chemicals and the state agencies that set MCS policy have become "subtle partners."

Despite pulling down $1.24 billion in profits last year, Boeing is looking to cut costs company-wide, industry experts say. The surfacing of an illness as complicated and potentially debilitating as MCS could be a harbinger of even tougher times.

With an estimated 20,000 employees spending their entire shifts around hazardous chemicals and thousands more having occasional exposure, Boeing could face huge medical costs and workers' compensation payments if MCS steers closer to the medical mainstream. One estimate has pegged Boeing's potential workers' compensation liability at $450 million. The expensive prospect of redesigning plants and changing manufacturing techniques also looms.

Observers say, however, that Boeing has shifted into damage control mode instead of doing what it can to prevent workplace illnesses in the first place. Boeing's in-house Health and Safety Institute, for example, has been underfunded and its efforts curtailed, according to a former institute researcher.

This defensive corporate response, observers say, only tends to make a solution to the MCS dilemma even more elusive. Already clouding the issue are the faulty memories of MCS victims, the secrecy that shrouds Boeing's operations, the dearth of well-controlled medical studies on MCS, and the silence of those hesitant to criticize the company.

"Everybody is scared to death of losing their job, but you're not going to need a paycheck when you're dead," said Schrum.

Despite these barriers, the anecdotal evidence describing the working environment at Boeing has begun to mount.

"Every Boeing worker I have talked to has horror stories about the working conditions," said Liz Moses of the Washington Toxics Coalition. "There are some severe problems over there, and there is no reason to assume Boeing is going to do the right thing."

John Kvasnosky, Boeing's top spokesperson for health and safety affairs, said neither he nor any other company official wanted to be interviewed for this article.

Auburn: Where It All Began

The 17-02 building at Auburn was reportedly built during World War II as cold storage for cadavers. Boeing later bought the building from the government and converted it for manufacturing. A large, unventilated structure, the temperature inside sometimes exceeded 100 degrees in the summer.

In August 1987, fiberglass pre-impregnated with phenol formaldehyde resins was introduced in the 17-02 shop, following new Federal Aviation Administration rules requiring more stringent flammability standards. Workers there performed "lay-up," making parts out of phenolic "pre-preg."

Faye Schrum worked at 17-02 as a plastic bench mechanic, wrapping layers of fiberglass, kevlar and graphite around molds to make parts for aircraft ductwork, cockpit dashes and panelling. These parts were then "baked" in huge ovens called autoclaves to set the materials in place. Some workers who did not work directly with the materials were stationed near the ovens, receiving blasts of hot vapors when the doors were opened.

|

'Everybody is scared to death of losing their job, but you're not going to need a paycheck when you're dead.' - former Boeing worker Faye Schrum

|

"I lost my husband," she said, "I didn't have anything better to do."

Heidi Guevara, another former plastic bench mechanic, recalls Friday potlucks when workers heated their food in the curing ovens. Didn't they worry about the health implications of this? "Honey, we were too far gone," Schrum remembered.

Experts note similarities between workers exposed to solvents and chronic alcoholics - they become addicted to the same stuff that makes them sick.

"We know that people with exposure to organic solvents have neurologic damage similar to alcoholics," said Professor Peter Breysse, a University of Washington industrial hygienist who studied the Auburn crisis. Breysse noted that the long working hours without days off compounded exposure problems.

"I'm lucky," said one worker, "I can still remember my name, age, and telephone number. There are people down there who are walking vegetables." Many chemically exposed workers tell of suddenly becoming lost or disoriented while driving and having trouble finding their cars in parking lots.

A key complaint at the 17-02 and other Boeing facilities was the lack of worker education and protective equipment. "None of us had respirators because none of us were certified (to use them)," recalled Schrum. "They gave us gloves that were extra large, but they came off when you put your hands down. What good is that?"

When the $26-a-pair gloves wore out, replacements were scarce. A supervisor once told Schrum, "If everyone went through safety gear like you do, this company would go broke."

According to workers, the rolls of "pre-preg" would visibly off-gas in the hot shop. Working as a parts clerk near the rolls, Billie McCormick began to feel headaches and stomach problems which became progressively worse.

illustration by Jenny Schmid

(click to enlarge)

Like many workers, McCormick entered a grueling period of working on and off, taking sick leave until she got better and then returning to work only to fall ill again. After spending time in the hospital, immunological tests confirmed she had been exposed to the phenol formaldehyde resin.

"People are running around in circles from doctor to doctor and they don't know what's wrong. We worked with so many different chemicals, they all got mixed together," Guevara said.

Dr. Gordon Baker, a Burien allergist, first saw the workers from the 17-02 building in early 1988. By 1989, he had seen 100 patients - two-thirds of them women - from the 17-02 and nearby buildings at Auburn. Half had skin rashes, two-thirds had memory lapses and suffered irritability, and 85 percent had respiratory tract irritation. Two-thirds had antibodies indicating formaldehyde exposure.

When federal and state inspectors visited the plants, however, chemical levels were measured within legal standards. One possible explanation: Workers said fans were brought in for extra ventilation during the inspections, and that inspectors frequently gave advance notice of their visits.

Dan Baker, a former worker at General Plastics Manufacturing Co. in Tacoma - where Boeing later subcontracted much its work, and employees also got sick - said the inspection routine is familiar.

"The state calls prior to the inspection. You shut down your line and clean up your crap," he said. Baker has chemical sensitivities from his exposure at the company and is involved in litigation.

By December 1988, Boeing said it had stopped using the phenol formaldehyde, but it still denied that the material had caused ill health. Dr. Patricia Sparks, head of Occupational Health Services at Providence Medical Center and a consultant to Boeing and other corporations, led a six-member panel that investigated the Auburn working conditions and health problems.

Although the panel found skin and upper respiratory tract irritations, it also emphasized that the workers suffered from anxiety and depression before the chemical exposure. The Sparks panel noted an atmosphere of "mass hysteria" due to stress, media attention and labor-management strife. (See related story: "The MCS Debate: A Medical Streetfight".)

UW Professor Breysse came to a different conclusion.

"My impression is that the workers didn't get proper training and weren't receiving hazard communication," he said. "Ninety-nine percent of the general practitioners have no experience in environmental health, and when they can't find anything, they think it's psychological."

Noting that many Auburn workers still suffer from their exposure to chemicals, Breysse noted, "This has gone on too long. These are not 'panic' people."

In testimony before the U.S. Senate in 1989, Harry Reid (D-Nev.), chair of the Subcommittee on Toxic Substances, asked Boeing Human Resources Vice President Joseph Peritore why the company discontinued the use of the phenolic materials, "despite the fact that you say there is no medical evidence supporting the threat to health?"

Peritore, who had just finished describing the Sparks panel's conclusions, replied, "Senator, I think that gives a good impression of how concerned about our employees' health we are. I am very disappointed if you feel that what I said in any way implies that we are not."

In his testimony, Peritore was quick to jump into the hole of doubt created by two sets of conflicting opinions: "Senator, when medical doctors disagree, our employees are hard put to know who is right. The fact that we believe the material was safe became irrelevant."

There has been no follow-up to the 1989 Reid hearings.

Stealth Poisons

Peritore was called to testify because of a similar incident that led to speculation about an "aerospace syndrome." Lockheed workers building the Stealth fighter at the company's famed "Skunk Works" in Burbank, Calif., suffered similar, if not more severe, health problems from using new composite materials while working in a World War II-era, unventilated building.

More than 600 workers later sued Lockheed; one is thought to have died as a result of his illness. Lockheed was ultimately fined $1.49 million by the federal government for safety violations. In 1992, Lockheed settled out of court for $33 million, much of which will be passed on to the government "as a legitimate cost of doing business," a Lockheed spokesman told the Los Angeles Times. Claims against the chemical manufacturers ended in a mistrial last year after the longest civil trial in U.S. history.

But Lockheed was not the only aerospace company using new Stealth composites. A similar though less-widespread problem occurred at the secret Developmental Center near Boeing Field in Seattle. In the late '80s, Boeing began building sections of the B-2 bomber and the Advanced Tactical Fighter using new materials made of carbon fibers impregnated with recently developed chemicals. The material absorbs radar signals, rather than reflecting them.

Internal Boeing documents offer a rare glimpse inside a company that apparently doesn't always put safety first:

As in Auburn, "lay-up" workers would hand-place layers of chemical-impregnated cloth and smooth them over a large "tool," which forms a mold, of sorts. The material is then cured in autoclaves.

Beginning in October 1988, the Boeing team working on the Advanced Tactical Fighter received a new material from DuPont that was pre-impregnated with a chemical called "Avimid K-III."

A month later, Boeing's industrial hygiene office released a series of "tip sheets" to workers using Avimid K-III, advising them of the material's dangers and the necessary safety precautions. The first tip sheet said no respirator was needed. Body wear consisted of disposable coats, pants and sleeves. For the hands, latex gloves were required.

Over the next 10 months, the tip sheets became progressively more stringent. Handwritten revisions started to appear on the sheets, stating that thicker butyl rubber gloves might be advisable, and that inhaling aromatic diamine, one of five highly-toxic components of Avimid K-III, may cause "eye damage."

DuPont had found earlier that aromatic diamine causes degradation of the eye's retina when inhaled. Despite having this knowledge, Boeing still did not require workers to use respirators.

|

'I would say I was a guinea pig. If a new chemical came in, they'd say, 'Oh, give it to Claire'.' - former Boeing worker Claire Parrott

|

Why did it take Boeing nearly a year to develop adequate protection measures for handling Avimid K-III? And, more importantly, did workers actually follow the guidelines in the tip sheets, such as using thicker butyl rubber gloves to prevent Avimid K-III's dangerous chemical components from being absorbed into the skin?

The evidence, obtained by an attorney during his client's workers' compensation case, indicates that Boeing hygienists knew about most of Avimid K-III's dangers before the company started using the material. However, they chose not to heed the warnings because the precautions slowed down the work and made it more difficult.

For example, a June 1988 Material Data Safety Sheet from DuPont noted, "Avoid skin contact. Butyl rubber gloves are recommended." Butyl rubber gloves were advised mainly because Avimid K-III contained a strong solvent called "NMP," which could quickly eat its way through the thinner latex gloves.

However, in a September 1988 memo, Boeing hygienist Thomas O'Keeffe downplayed the presence of NMP, noting that "minimal amounts of the solvent are expected to be present" due to earlier curing stages at DuPont's manufacturing plant.

O'Keeffe also wrote that "lay-up operations using butyl gloves would be very difficult to perform," because the thicker gloves reduce tactile sense and manual dexterity, making the work slower and more prone to bubbles and wrinkles.

Yet a DuPont study relayed to O'Keeffe several months later clearly showed that latex gloves "broke through" in less than an hour when exposed to the NMP solvent. A DuPont toxicologist later stated in a deposition that, "I think you would be ill advised not to follow the recommendations given within the MSDS to prevent personal exposure."

(Over at the Auburn plant, according to documents, workers wore the thicker butyl gloves when cleaning out residue from autoclaves where the Avimid K-III parts were cured.)

'To Protect the Parts'

The resulting health effects to one worker at the Development Center were severe. Lay-up worker Claire Parrott handled Avimid K-III in a cordoned-off area near the plant's heating unit. For security reasons, "There was a big black sheet draped around the whole area," said Parrott's attorney, William Knowles of Seattle.

Parrott said the only gloves she wore were nylon liners, latex gloves and, for a brief period, slightly thicker yellow gloves. It turns out, however, that those broke down even faster than the latex gloves. She never wore a respirator, even during "tear up" of parts, a process that releases dust.

"There were times when I literally lost my hair - it came out in golf ball-size chunks," Parrott said. "I was in tears. I should have realized that something was wrong.

"I would say I was a guinea pig. If a new chemical came in, they'd say, 'Oh, give it to Claire.'"

Parrott said she never saw the tip sheets, nor did she know the names of the chemicals she worked with, only the special numbers assigned to them by Boeing. Gloves and garments were to help keep the parts, not the workers, from being harmed.

"It wasn't for our protection," Parrott said, "it was to protect the parts."

Parrott developed occupational hepatitis and severe skin problems, including "dermagraphia," which resembles hives or nettle stings. Dr. Gordon Baker has also diagnosed her with organic brain poisoning. The Board of Industrial Insurance Appeals approved her claim for the skin problems only.

After lengthy litigation - in which Boeing initially denied access to company records to Parrott's attorney - King County Superior Court eventually ruled that Parrott suffered from occupational hepatitis and was entitled to compensation. Parrott still suffers from skin problems, chemical sensitivity and neuro-psychological problems.

In depositions, attorney Knowles discovered that DuPont knew little more than Boeing about Avimid K-III's health dangers. A DuPont toxicologist admitted the company only did studies on Avimid K-III's five individual components and knew little of their combined interaction. Moreover, toxicity and exposure-limit studies on rats were only done on the effects of inhalation, not skin absorption.

And despite federal rules limiting skin exposure of aromatic diamine, Boeing only monitored workers for air concentrations, not skin absorption. With a plethora of new Stealth and composite materials in use at the Developmental Center, Knowles estimates that one out of four of the complex's workers got sick from 1987 to 1992.

Exposure to chemicals was not limited to lay-up personnel at the Developmental Center. Office workers and engineers working on computers on the building's higher floors were reportedly affected by chemicals wafting up. But because access to certain areas was limited on a "need-to-know" basis, office workers knew little about what was going on around them or what materials were being used.

|

'The scorched-earth defense sends a message: 'If you attempt to file this claim, we will squash you'.' - attorney Matt Sweeting

|

In October 1989, the state L&I fined Boeing $128,780 for 36 health and safety violations at the Developmental Center. Because they did not have security clearances to the top-secret Developmental Center, L&I inspectors were forced to bring in federal inspectors to act as chaperones.

The infractions included four "willful" violations of chemical handling practices or inaccessible Material Safety Data Sheets. ("Willful" violations are classified as those where death or injury could result, and the employer was aware that a hazardous condition existed and made no reasonable effort to correct it.)

Boeing appealed the fines and in May 1991 paid the state $41,000.

The Developmental Center is also the site of the infamous "Strom case." Robert Strom was a 29-year Boeing engineer who developed leukemia after he claimed he was unknowingly exposed to electromagnetic pulse, or EMP.

EMP is the burst of electrical energy emitted by a nuclear explosion that disables communications and electrical equipment. While trying to design electrical equipment impervious to EMP, Boeing exposed Strom and more than 700 other employees between 1983 and 1985.

Strom argued that Boeing knew all along that he was being exposed to EMP and took blood samples from him on a regular basis. Boeing medical personnel never told him he was in danger.

For years, Boeing fought Strom's claims through state and federal courts, finally settling with him and other employees. Boeing gave Strom a $500,000 out-of-court settlement and agreed to pay 10 years' worth of medical monitoring for 300 workers, said his attorney Michael Withey of Seattle. The monitoring is being supervised by Dr. Patricia Sparks, the controversial Boeing and L&I consultant.

Strom recently had a bone marrow transplant and is doing well.

A Bureaucratic Nightmare

Before sick or injured Boeing workers ever go to court for relief, they usually start out in the Kafkaesque world of workers' compensation claims, insurance companies and independent medical examiners. To survive being snowed under by flurries of paperwork, workers will often maintain as many as 10 binders of documentation, labelled by doctor, insurance company or government agency.

Like many government-run programs, Washington's workers' compensation system is a labyrinth of red tape and arcane language that can befuddle even someone not suffering from memory loss and disorientation.

Basically, here's how it works:

As a self-insured company, Boeing initially decides whether it will cover a medical test for a worker claiming to be hurt or sickened on the job. And it is Boeing that initially decides whether to approve a claim for workers' comp benefits. For problems such as a broken leg, these decisions are relatively cut and dried, as long as it can be "objectively" shown that the broken leg was caused by a workplace condition.

But the furious medical debate surrounding MCS has complicated matters for people who suffer from the condition. Because there's no medical consensus on what causes MCS, or how to diagnose or treat it, the state's "objectivity" test is nearly impossible for MCS patients to pass.

Plus, MCS is not recognized by the international body that categorizes diseases and illnesses. So even if a worker can "objectively" show that workplace chemicals caused him or her to contract MCS, Boeing and the Department of Labor and Industries will reject the claim.

Making matters still worse, Boeing has a policy of refusing to pay for the tests customarily used by Dr. Gordon Baker and other specialists to diagnose MCS. This is because Boeing and the state Labor and Industries department do not recognize these tests as "objective" ways of diagnosing MCS, which is also not yet recognized by Boeing or L&I.

In order to receive benefits, then, sick workers must match up one of their specific health problems to a condition for which Boeing will pay workers' comp. Many have won claims, for example, based on occupational asthma, toxic encephalopathy and rhinitis.

"Boeing has accepted individual claims, but it has not acknowledged the existence of this new medical condition," says attorney James Hailey, who represents about a dozen of the injured Auburn workers.

This policy forms the basis of an interim policy released last October by L&I, which essentially denies the use of diagnostic tools that specialists in the field claim will objectively diagnose brain damage and other physiological problems from chemical exposure.

The proposal is being supported by the Washington State Medical Association and some doctors who have connections with Boeing. MCS sufferers and some of the doctors who treat them, however, have been highly critical.

"We were aghast at the policy," wrote Dr. Allan Lieberman of the Center for Environmental Medicine in North Charleston, S.C. "The decision to deny payment for [certain] tests is like asking, 'Mother, may I go swimming?' and receiving the response, 'Yes my darling daughter, but don't go near the water.'"

Sue Ammeter, chair of the Governor's Committee on Disability Issues and Employment, also criticized the policy, arguing that it may prevent people from getting the tests they need.

'The Scorched-Earth Defense'

For many, the claims process is the most frustrating and degrading part of their chemical exposure ordeal.

Ill and confused from a little-understood illness, and worn down by a harsh system that questions their very sanity, MCS patients say the system pushes them over the edge. Many are subjected to psychological testing and grillings about childhood family problems.

Some women have reported being told by L&I claims adjustors that they're just having a bad case of PMS.

"You have no idea how they have humiliated us," said a former Boeing worker who asked not to be named. "You don't feel like a person." Another said, "They assassinate your character in those exams."

Attorney Matt Sweeting of Tacoma has seen Boeing's tactics used on many of his clients.

"The scorched-earth defense sends a message: 'If you attempt to file this claim, we will ask you intimate questions about your life. We will squash you.'"

Despite winning a judgment in King County Superior Court on her workers' compensation case, Claire Parrott is reduced to living on Social Security and her Aetna life-insurance policy taken out through Boeing. Many of the former Boeing workers draw down on this policy at $300 a month until they use up the $15,000 limit.

"You pay into a system, then they are not there to help you. That's not right," Parrott said.

Heidi Guevara had a particularly bad three-month period in 1988, in which she saw Dr. Sparks ("I thought that woman was there to help me," she said of Sparks), was given an AIDS tests because of her skin sores, and was denied compensation claims. Guevara then tried to kill herself with pills and Bacardi 151 and spent 13 weeks in Valley Medical Hospital.

Like Parrott, Guevara now lives on Social Security and her Aetna life insurance of $300 a month. "It's devastating," Guevara said. "My daughter moved back home to take care of me."

Many sick workers understand that Boeing is trying to limit its liability by sending them to company-hired independent medical examiners (IMEs). But they resent the IMEs' inquisitorial, skeptical and, at times, rude demeanor.

"Mean isn't the word," said Parrott, who frequently returned from IME visits in tears. "They would say, 'Oh, you're one of them.' They're making us look like a bunch of hysterical women." Parrott said that before she got sick, Boeing had several times made her an "employee of the month."

In other cases, workers have had to wait months for their medical reports to be sent to the state for review. One worker said pieces of her file that could have helped in her appeal never made it to Olympia; she had to get her own copies and mail them herself.

Many chemically injured workers - and not just those from Boeing - are afraid to speak on the record for fear their cases will be denied at the Board of Industrial Insurance Appeals. Those still on Boeing's payroll fear retribution from the company.

'Expediting My Butt Out of the System'

L&I's new headquarters is a flashy glass building off Interstate 5 in Tumwater. It has a sweeping, glass-enclosed atrium that seems more suited to many downtown corporate cathedrals than a bureaucratic backwater outside Olympia.

|

'If L&I doesn't want to take respon- sibilty for it, they should get the hell out of the insurance business. I'm not a disposable person.' - MCS sufferer Don Stanberry

|

"There are a few doctors who are seeing these people and labelling them as MCS cases. The overall medical community might see some of these doctors as (out) on the fringe."

Nonetheless, L&I has set up a special claims unit to handle what they call "chemically related illnesses" - not MCS - and 85 new and old cases are under review. (About 200 MCS sufferers file workers' comp claims each year.) Attorney Sweeting said, however, it will take nothing short of new legislation before closed cases that were denied can be reopened. And workers say the unit has done little to expedite their claims.

"The only thing they are expediting is my butt out of the system," said Don Stanberry, whose exposure to solvents at a Seattle car lot for three months in 1988 has left him chemically sensitive.

"If L&I doesn't want to take responsibility for it, they should get the hell out of the insurance business. I'm not a disposable person," Stanberry said.

Under former Director Joe Dear, hired by former Gov. Booth Gardner, L&I's workers' compensation fund went from having a deficit to a $350 million surplus. Workers charge that Dear turned around the agency's deficit at their expense.

Last year, Dear was plucked from Olympia to run the federal Occupational Safety and Health Administration, an appointment fought by MCS activists but ushered through confirmation by Sen. Patty Murray.

"I don't feel that Joe Dear was a friend to the injured workers of this state," said attorney Randy Gordon who, along with Hailey, represents some of the Auburn workers.

Last year Mark Brown, deputy director and head lobbyist for the Washington Federation of State Employees, took over at L&I. Since then, Brown claims that MCS is the only issue he has lost sleep over.

When encountered by chance in the elevator at L&I headquarters, Brown told the Free Press that he believes MCS patients are "really sick." His outward compassion, however, seems inconsistent with internal L&I policy decisions.

In January, for example, L&I officials touted a proposal for new indoor air quality standards. (Two-thirds of MCS sufferers received their precipitating exposure in offices.) However, following pressure from the state business lobby, the standards were quietly withdrawn, save for a ban on smoking.

"Brown was concerned about seeming too liberal and bent over backwards to the business community," attorney Hailey said. "They are stacking the deck in favor of the conservative approach."

Boeing: A Political Force Like No Other

Anybody possessing even cursory knowledge about Boeing knows of its tremendous political clout. After all, you don't get to be the biggest company in the state and the largest exporter in the country without making a few connections here and there.

Over the years, Boeing's lobbyists have proven to be nearly invincible in Olympia, and candidates backed by the company in local, state and federal elections have been mildly successful at achieving and maintaining public office, to say the least.

So strong is the company that a high-ranking state environmental official admitted in the late '80s that Boeing enjoyed a "protected status" that shielded the company from serious scrutiny.

Boeing's approach toward MCS has been no less aggressive.

A review of government records and interviews with key political and medical players reveals the depths of Boeing's influence over medical research and the state's worker's compensation system. In seeking to manage the debate over MCS and limit its potential ill financial effects on the company, Boeing has turned most often to the University of Washington's Medical School (including the UW-run Harborview Hospital), the highly influential Washington State Medical Association and the state Department of Labor and Industries itself.

Of all the connections that could be documented, perhaps the most disturbing fan out from the controversial "Simon Study."

Published last year, the Simon Study was co-funded by Boeing through its in-house Health and Safety Institute, an ostensibly non-biased research arm of the company. The study, which opines that MCS is related to psychological problems, has come under criticism (See related story: "The MCS Debate: A Medical Streetfight".).

Leading the study's five-member team was Dr. Gregory Simon, a psychiatry and behavioral sciences instructor at the UW medical school who now works out of Group Health.

Joining Simon on the Boeing-funded project was Dr. Henry "Hal" Stockbridge, who was soon to become L&I's associate medical director and a key player in the state's response to the needs of MCS sufferers. Helping to recruit subjects to be studied was Dr. John Holland, who was recently named as the medical consultant to L&I's much-touted MCS claims unit, which was formed in December exclusively to review worker's compensation claims submitted by MCS patients.

Stockbridge's intimate involvement in the Simon study was defended by his boss at L&I, Dr. Gary Franklin, the department's medical director.

"Stockbridge was a resident when he started that project. He did not have any personal relationship with Boeing," Franklin said.

Also assisting on the Simon study was Dr. Stanley Bigos, a UW orthopaedics and environmental health professor who co-directed another Boeing-funded study on workplace hazards. In language reminiscent of the Simon study, Bigos' 1991 study on back injuries at Boeing plants determined that "psychosocial" factors such as denial of emotional distress played a large role in workers' decisions to report back problems.

Even before the Simon study was released, a number of articles appearing in medical journals were skeptical about whether the phenol formaldehyde used at the Auburn plant actually caused the workers' health problems.

Among the co-authors of these articles was Dr. Rick Johnson, a UW associate professor of medicine, an active member of the Washington State Medical Association and a participant of the "MCS Working Group," a panel being set up by the state L&I to study various MCS issues. Two other authors, Dr. Leonard Altman, a UW oral biology professor, and Dr. Garrison Ayars, a UW professor of medicine, served on the Boeing-hired panel that reviewed the cases of workers sickened at the Auburn plant.

The fingerprints of the UW School of Medicine are all over the literature published about the sick Auburn workers: Of some 16 doctors involved, 13 teach at the school. Since 1985, Boeing has given $139,111 in research money to the medical school and affiliated academic departments, according to a UW spokeswoman.

Franklin, an associate professor of environmental health at the UW, said the connections among these institutions make perfect sense.

"The conspiracy theory says that Boeing and the UW are in cahoots. But it's not that uncommon for a company that has a problem to fund research. If they didn't, who else would?" he said.

In an apparent contradiction, however, Franklin said that research into MCS was suffering because a lack of "independent" funding. He drew comparisons to the problems with Agent Orange, saying that "a lot of research into that was driven by politics."

Adding fuel to the fire over the Simon study, a Boeing-hired attorney obtained a copy of the study before its results were published, the Free Press has learned. The attorney, Gary Keehn of Seattle, surprised rival lawyers when he produced the study in the course of defending Boeing in a lawsuit filed by a worker sickened at the Developmental Center. (See related story: "The MCS Debate: A Medical Streetfight".)

The Network Grows...

Around the time that the Simon study was being readied for release, a handful of leaders from the region's corporate and medical worlds hooked up with another powerful force, the Washington State Medical Association, to form the Northwest Association of Occupational and Environmental Medicine (NAOEM).

According to records from the Secretary of State's office, sitting on the Association's nine-member board are several people working intimately on MCS issues, some of whom have been trying to keep MCS standing out in the hallway.

Among them are:

- Dr. Dennis Stumpp, Boeing's former manager of occupational medicine programs. Stumpp said he left Boeing last year to join Dr. Patricia Sparks in the occupational medicine department at Providence Medical Center to "build on some of the things she's done;"

- Dr. Holland, Labor and Industry's MCS consultant; and,

- Dr. Joel Kaufman, acting director of Safety and Health Assessment and Research for Prevention, the medical research arm of L&I.

(Also serving on the board are Dr. Michael Holthouser, former medical director for the Weyerhaeuser Co. and now the medical director for GE Plastics in Pittsfield, Mass., and Dr. Margery Swint of the Hanford Environmental Health Foundation (HEHF), a U.S. Department of Energy contractor that provides health services for Hanford workers. Hanford watchers say whistleblowers at the site have been sent to HEHF for psychological tests to deter them from going public, and that HEHF has helped squelch epidemiological studies that shed a critical light on the effects of radiation exposure.)

|

'She's trying to straddle too many fences.' - IAM's Buck Cameron on Dr. Patricia Sparks

|

Stumpp was unspecific when asked what the Association does. But he said most of its members "are on the side of science, not on the side of advocacy for MCS as a legitimate medical claim.

"The issue is scientific, but it has been politicized by a small but vocal group of people," the ex-Boeing physician said.

Seeking to play on the fears of Mr. and Mrs. Air Traveler, Stumpp said the MCS issue should be of concern to "taxpayers," whom he hinted would ultimately pay higher plane fares if Boeing is forced to pay more in worker's compensation benefits.

Other NAOEM board members did not return telephone calls.

State records indicate that the registered agent for NAOEM is Williams, Kastner & Gibbs, the seventh-largest law firm in Puget Sound. Among the Seattle-based firm's biggest clients are Aetna, Boeing's former insurance carrier, and Alaska Airlines. The firm is currently defending the airline in a worker's compensation case filed by several flight attendants who say they have mysteriously taken ill from working inside Alaska Airlines' planes.

(Sickened flight attendant Carmen Allum of Tacoma said that the Williams firm hired a private detective to surveil her with a hidden camera outside her home and while doing errands, in hopes of showing that she wasn't truly disabled and therefore ineligible for benefits. The film, however, showed her tripping and falling down on the street, Allum said.)

Jerry Edmonds, managing partner of the Williams firm, could not be reached to comment on the connection with NAOEM.

Now How Much Would You Pay...

There's another affiliate of the State Medical Association that's influencing how the state handles worker's compensation claims from MCS patients. The Association's Industrial Insurance & Rehabilitation Committee told L&I Director Mark Brown in a strongly worded letter last October that the state's policymakers "are being overly influenced by a few activists and [health care] providers whose views do not represent those of mainstream medicine."

Among its supporting evidence, the committee points to work done by researchers at the UW.

The irony of the Medical Association's letter is that, according to state records, it was based on the opinions of Dr. Patricia Sparks, the Boeing and L&I consultant whose connections, public comments about MCS and admonitions of doctors with whom she disagrees have made her - willingly or not - a highly political figure in the debate.

Sparks has been a lightning rod attracting conflict-of-interest accusations since emerging as an ubiquitous figure in the MCS debate.

It's no wonder: Sparks is currently being paid by L&I to review workers' compensation claims, and by Boeing as an occupational medicine consultant. She also has written a number of medical journal articles and letters to public officials questioning the use of certain diagnostic tests on people claiming to have MCS, and attributing many of their symptoms to psychological factors. (See related story: "The MCS Debate: A Medical Streetfight" for more on Sparks.)

Sparks' diverse career can make her tough to read. In an apparent contradiction to her views on the Auburn crisis, for example, Sparks cautioned General Plastics - the Tacoma subcontractor where workers suffered from exposures to toxic solvents - to take their employees' safety concerns seriously.

"A significant number of employees are having symptoms and signs of illness which are 'real' and not 'hysterical,' and which are quite distressing to them," Sparks wrote in a 1991 letter, citing the "folly of employers not heeding employee's concerns and relying strictly on industrial hygiene data."

People are taking notice of what seem to be Sparks' inconsistencies.

"She's trying to straddle too many fences," said Buck Cameron, an industrial hygienist for the IAM District Lodge 751. "There's certainly an appearance of a conflict when you have something about which so little is known. And appearances can be everything."

Sensing a building political and public relations problem, L&I Director Brown announced last summer that Sparks would no longer consult for the department on worker's compensation claims from MCS patients. Tacoma attorney Matt Sweeting has told the Free Press, however, that he personally knows of three MCS sufferers whose cases were reviewed by Sparks in the past six months. Sweeting would not reveal the persons' names, in order to maintain their anonymity.

Despite the growing controversy, L&I medical director Franklin said he's sticking by Sparks.

"She's not getting too hot for me to handle," he said. "The problem is that you need to get medical opinions in these cases, and her reputation is that she is one of the best occupational physicians in the Northwest."

Business/Politics as Usual

While political and economic powers may slow the reform of the state's MCS policies, a combination of many problems got us into this mess in the first place. When looked at in tandem, these factors raise profound questions about how chemical-intensive companies such as Boeing balance the attainment of profits against the needs of workers, and about Boeing's very corporate persona.

Near the top of the list of past failings is the inability of modern medicine and modern science - which find "solutions" by dissecting a problem - to deal with a systemic condition as complicated as MCS.

|

'It's stupid to say that you have to injure people before you have proof that there's a problem. Think of how many people were hurt before asbestos became an issue.' - Liz Moses, of the Washington Toxics Coalition

|

"There is a tremendous amount of interaction among different systems of the body," said Liz Moses of the Washington Toxics Coalition. "But has that understanding made its way into how medical research is done? There is very little that we know about chronic, 'low-level' exposure to toxic chemicals."

With the phenol formaldehyde problems at the Auburn plant, for example, inspectors detected levels of each individual chemical below government standards. But these standards are not written to take "toxic soups" into account, and there's a shortage of research that can help predict how people will respond to a chemical melange, Moses said.

Plus, Moses said, most government chemical-exposure standards go back at least 25 years, and they were written with industry's needs in mind.

Striking a familiar chord, Moses cited a pattern of allowing dangerous conditions to persist for many years before government policies and ways of doing business change. Meanwhile, people suffer.

"It's stupid to say that you have to injure people before you have proof that there's a problem. Think of how many people were hurt before asbestos became an issue," she said. "We need to focus on precaution."

But what is proof? To this day, the Tobacco Institute continues to preach to credulous elements of society that there's no definite link between cigarette smoking and lung cancer.

'I've Wrestled with the Devil'

Where government efforts to protect workers fall short, employees often look to their company to come up with its own safety net. Some efforts by Boeing, however, have been met with disappointment.

For example, the company's in-house Health and Safety Institute has suffered from front-office meddling, said Meg Murch, a Boeing worker whose two-year assignment at the Institute just recently ended.

"There has been resistance to the Institute," said Murch, who is back at her regular job building model airplanes at Plant 2, "and I would expect that to continue. I don't think there's going to be easy sailing."

|

'The company has learned how to drain money out of the Institute. It has put the brakes on a lot of what it was doing.' - Boeing worker Meg Muerch

|

To fund the Institute, Boeing chips in 4 cents for every hour that an IAM member works, said the IAM's Buck Cameron, who is on the Institute's board. Boeing currently is spending $4 million a year on the Institute, which is the minimum level allowed under its bylaws, Cameron said.

Of Boeing's funding commitment, Murch said: "The company has learned how to drain money out of the Institute. It has put the brakes on a lot of what the Institute was doing."

For example, Cameron said, the Institute is supposed to be studying the possible connections between the symptoms of sick workers and chemicals used in Boeing plants. So far, it hasn't happened.

"The company is not interested in making that link," Murch said. "When you get down to finding scientific evidence, nobody wants to do it."

Murch also said she's been disappointed by the company's efforts to improve the way workers are told how to handle dangerous materials.

It was the lack of safety information that played a role in the death of maintenance mechanic Bill Cleland, who died from third-degree burns he suffered at the Auburn plant on Aug. 27, 1990, according to L&I records. The fire, touched off by sparks from Cleland's motorized cutting tool, led an L&I inspector to consider citing Boeing with a "willful" violation, records show. "Boeing has been cited on hazard communication training in the past," an L&I industrial hygienist wrote.

"I've wrestled with the devil trying to do a hazardous communications program that was worthwhile," Murch said, adding that workers' access to safety information varies from plant to plant. In some areas, for example, workers have not been taught how to use the computers that store the information, Murch said.

Improving these programs is critical, Murch said, in part because different plant supervisors approach safety issues differently.

"Some of them say 'Stop faking it - Stop fucking around and get back to work.' Others say 'Stop working and let's find the problem.'"

One area of improvement has been the recent training of the company's health and safety committees assigned to each of Boeing's nine main facilities. For about 40 years - up until two years ago - the committee members were untrained. "They guessed the best they could," Cameron said.

Committee members now take 120 hours of training through the National Safety Council, Murch said.

With Boeing officials refusing to be interviewed, the Free Press could only refer to a year-old statement about the company's approach to worker safety issues.

"Safety and health in the workplace ... are integral to The Boeing Company's business plans and factory operations. [Our] initiatives underscore Boeing's commitment to the well-being of its employees."

'Somebody Has to Pay'

With MCS still in its infancy in medical and political circles, only a few specific proposals to deal with the illness have yet to surface in the halls of government.

Among them is a bill now moving its way through the state Legislature that would:

- Require L&I to establish by the end of the year an interim set of criteria and procedures for handling claims from the chemically injured that would "ensure consistency and fairness;"

- Require L&I claims managers to have expertise in the field of chemically related illnesses;

- Create an advisory committee to consult with L&I and other state agencies that work with the chemically disabled; and

- Use L&I money and a special tax on Boeing and other self-insured companies to pay for research on chemically related illnesses. (The UW has been mentioned as a possible home of MCS research. But talk around the Capitol suggests that the idea may be scrapped.)

Pushing HB 2696, which moved out of the House Commerce & Labor Committee Feb. 2, is Rep. Michael Heavey, a Seattle Democrat whose own perplexing back problems have given him a perspective on medical mysteries.

"There is no test that can show that I have a bad back, yet it would qualify for worker's comp even though I can't prove it," Heavey explained. "If enough people with MCS pile up so that it seems so overwhelmingly objective, you might believe objectively that it is a problem."

Stephen Gockley, of the governor's Committee on Disability Issues and Employment, also thinks hard science may have to take a back seat to compassion.

"There have been cases in the last 20 years where the medical community was the last to acknowledge other forms of chemically related illnesses. Meanwhile, people went untreated and unsupported," he said. "If we are going to be at the forefront in dealing with this issue, we shouldn't make a scientific judgment. We should make a social program judgment."

Gockley, however, said he fears that continuing tough economic times and the anti-tax movement may work against efforts to provide relief for MCS sufferers.

At the governor's office, aide Nate Ford says Lowry's exposure to the unfolding MCS dilemma is basically limited to updates from L&I Director Mark Brown.

Viewed as a friend of MCS sufferers, the liberal governor has talked with chemically injured workers at a few public events, including a Labor Day picnic at Seattle's Woodland Park last year and a "town meeting" in Tacoma. Whether Lowry will get personally involved with finding solutions, however, remains to be seen.

|

Research for this story was supported by a grant from the Fund for Investigative Journalism in Washington, D.C. |

Related Stories/Resources:

Suicide Solution - One Woman's Way Out

Disunity Among the Machinists

The MCS Debate: A Medical Streetfight

On Top of Everything Else, Sick Boeing Workers Face Judicial Hurdles

Resources

Please see "The Boeing Story (No, not a retraction. A vindication.)"

|

|

|

|

|

Contents on this page were published in the February/March, 1994 edition of the Washington Free Press.

WFP, 1463 E. Republican #178, Seattle, WA -USA, 98112. -- WAfreepress@gmail.com

Copyright © 1994 WFP Collective, Inc.